Picasso and your house paint

| Did you know that Picasso used regular house paint for many of his most famous paintings?Apparently this has been a source of argument between art historians for years, but it was recently settled by scientists in the US. They used a high-energy X-ray instrument called an x-ray nanoprobe to examine tiny pieces of paint – pieces about one thirtieth the thickness of a piece of paper.The results showed chemicals including zinc oxide, which suggested house paint. They needed some house paint from Picasso’s time to compare it, and managed to find some on Ebay (I’m liking these scientists already).

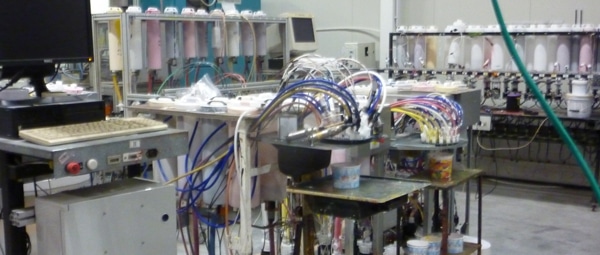

Volker Rose, physicist at the Argonne National Laboratory in Chicago, published the results of his study in ‘Applied Physics A: Materials Science & Processing’: “We were looking into pigments taken from Picasso’s white paint, which from a material perspective is zinc oxide, and we were able to study the impurities that are there,” Dr. Rose said. Picasso was apparently one of the first major artists to switch from traditional artists’ paint to house paint, which is not only more affordable but also creates a glossy image without brush strokes. So if you’ve ever wondered what painters think about in between cups of tea, now you know. We’re all closet intellectuals. But it started me thinking about paint and what it’s made of. The oldest known paint was found in South Africa about two years ago – it was an ochre-based mixture 100,000 years old. Cave paintings are probably about 40,000 years old. Egyptian paintings using a wider range of colours go back about 20,000 years. Sometimes we are asked to use paint that people have had under the stairs which looks old enough to have come from under a pyramid. Paint now generally consists of four main parts: solvents to make them fluid, resins to create a film, pigments to provide colour and, nowadays, additives such as antifungicidals. Most pigments are dry colorants ground into fine powders, for better durability. Pigments conform to strict International Standards Organization standards. Many paint manufacturers have also voluntarily adopted the Colour Index International (CII) to identify the pigments to use in manufacturing particular colors – though any decorator will tell you that matching colours can be a real headache, even using the same product from the same manufacturer. The paint components are mixed together into a paste and processed in a high speed dispersion tank, where the mixture is thoroughly blended. This is the process which gives customers the ability to choose from thousands of shades and to have colors custom matched. I pointed out to one customer that if you compare our prices to the cost of a Picasso, he was getting a bargain. For some reason, he didn’t seem completely convinced. All the best,

|